Investing in electric forklift trucks makes great environmental sense, but what are the costs involved? An electric fleet could actually help you cut your material handling expenses, yet there are still some misconceptions about what electric trucks can offer.

Although you may be unsure about the initial purchase price, your costs don't stop with hardware. That means that it's far more useful and accurate to look at TCO (total cost of ownership. If you take into account all the different factors that make up your actual material handling spend, you may soon find that you gain greater value from an electric forklift.

Read on for answers to some of the key questions fleet operators and operations managers ask about electric forklifts, and to learn more about the cost-effectiveness of operating an electric forklift fleet.

Related read: 6 Key Advantages of Electric-Powered Forklift Trucks

How much will it cost me? Don't electric forklifts cost more?

It is true that an electric truck is generally more expensive to buy than its non-electric counterpart, but there is more to take into consideration than just the initial outlay. First of all, diesel trucks generally use older engine technologies, whereas an electric truck will be equipped with more modern technologies for economy and efficiency. The latest trucks will also have onboard diagnostics that help you reduce downtime, as well as features to protect productivity by increasing operator comfort, for instance.

Secondly, electric trucks are competitive when it comes to running costs, as charging them is often cheaper, easier, and safer than refuelling a diesel or LPG truck. Since electric trucks are on par for quality and capability, this is good news for your long-term ROI (return on investment).

Related read: How Much Will the Electrification of Your Forklift Fleet Cost?

Warehouses also run the risk of incurring costs via damage to items. TCM order pickers are engineered to handle delicate and fragile items safely. They often come equipped with features like cushioned mast mounts and advanced load stabilisation systems, ensuring minimal product damage during handling and transportation.

Discover the key specifications of the EO: TCM’s medium and high-level order pickers here.

By reducing the occurrence of damaged goods, businesses can avoid losses associated with replacements, returns, and unsatisfied customers.

To add, our order pickers are equipped with safety features such as operator presence sensors, anti-slip platforms, and programmable speed controls.

By ensuring a safer working environment, these machines minimise the risk of accidents, injuries, and associated costs, including medical expenses, worker compensation claims, and potential legal liabilities.

Will my electric truck have the same abilities as a non-electric one?

It’s a misconception that electric-powered vehicles aren’t up to the same tasks as their engine-powered equivalents. As technology has improved, so too have the capabilities of electric trucks. So not only are they cleaner and better for the environment, but they match the material handling capabilities of engine forklift trucks.

Related read: How Electrification Can Enhance The Efficiency of Material Handling

You can also expect to see the continuation of this trend as owners expand their electric fleets due to changes in emissions regulations. The demand for ever-better electric warehouse equipment will continue to drive innovation in this sector.

By 2030 it will no longer be legal to sell new gas, diesel or hybrid-powered vehicles (in the UK).

Download your free checklist here to ensure you’re prepared for 2030.

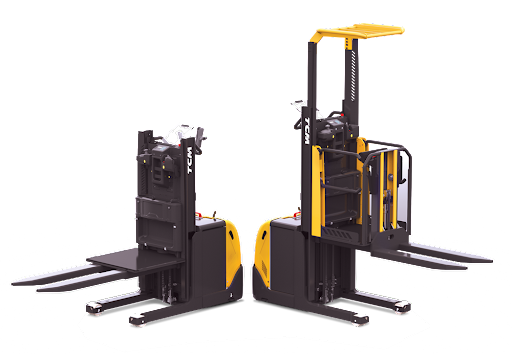

Take TCM’s electric order pickers, for example. Order pickers are designed to operate in compact spaces. This means they’re ideal for warehouses with limited room.

By utilising the vertical space effectively, these machines enable high-density storage and efficient use of available storage capacity. Maximising vertical storage minimises the need for extensive warehouse expansions or additional off-site storage, ultimately reducing material handling costs.

Electric vehicles come with the added benefit of working seamlessly with warehouse-specific software: TCM order pickers can be integrated with warehouse management systems (WMS) and other software solutions, enabling seamless communication between the forklifts, operators, and inventory systems.

This integration enhances the order fulfilment process by providing real-time inventory data, optimising pick routes, and facilitating efficient task allocation. A streamlined workflow improves order processing speed which reduces downtime and improves TCO.

Explore the full TCM order picker range with this brochure.

By leveraging the capabilities of TCM order pickers, businesses can experience increased efficiency, accuracy, space utilisation, safety, and streamlined operations. These improvements result in cost savings, higher productivity, and an improved ROI in material handling operations.

What about the cost of maintenance?

Electric trucks used to cost more to maintain. However, this is an area where costs are coming down as familiarity with battery and charger technology starts to become the norm.

Not only that, batteries today require little-to-no maintenance and electric-powered vehicles have fewer moving parts, making them less likely to break down, which reduces costs and improves TCO.

Related read: Key Features and Benefits of Lithium-Ion Battery Technology

Are electric trucks higher maintenance than diesel?

Whilst operators still need to carry out regular checks on electric-powered vehicles, electric forklifts don’t require more maintenance than diesel or LPG-powered forklifts.

Read this article for 5 Electric Forklift Maintenance Tips to Protect Your Equipment.

One thing that will become clear is that better awareness of how to look after your truck protects your investment. Understanding correct battery maintenance can help you operate more efficiently and safely. Encouraging this mindset among your workers will have positive effects on your overall material handling costs.

Is it true that electric trucks last longer than diesel ones?

Electric forklift trucks generally have a longer lifespan than diesel forklift trucks due to a few key factors:

1. Electric forklifts have simpler designs with fewer moving parts, resulting in reduced maintenance requirements and costs. They typically have longer service intervals and fewer components that need replacement or repair.

2. Electric forklifts do not have combustion engines, which means they experience less engine wear and have longer operational lives.

3. While electric forklift batteries have their own lifespan, advancements in battery technology have improved their durability and efficiency. With proper maintenance and charging practices, their lifespan can be maximised.

In terms of increased efficiency, TCM order pickers utilise lithium-ion or lead-acid battery power, enabling faster and more efficient warehouse operations when picking items from racks or shelves. These machines are built with features like elevated operator platforms, ergonomic controls, and adjustable forks, allowing operators to reach higher shelves and access items with ease. This efficiency leads to higher productivity and reduced labour costs.

Related read: Warehouse Motivation: 5 Reasons to Invest in Electric Order Pickers

- While electric forklift batteries have their own lifespan, advancements in battery technology have improved their durability and efficiency. With proper maintenance and charging practices, their lifespan can be maximised.

- While electric forklift batteries have their own lifespan, advancements in battery technology have improved their durability and efficiency. With proper maintenance and charging practices, their lifespan can be maximised.

Is it true that you can't use electric trucks outside?

To get great ROI in your warehouse operations, you'll want your purchase to be right for the tasks your drivers perform. The more versatile your equipment, the better the TCO.

Find out more about TCO and understand material handling costs here.

The idea that electric trucks can't be taken outside is another misconception. Instead, modern forklift trucks are equipped with practical design features such as protected electronics and weather-resistant exteriors. If you have questions about this, your local dealer can help. They can tell you if a truck has the features you need for your operations. They can also advise you about the truck's warranty.

Can I use accessories and attachments with electric trucks?

Yes. In fact, the release of larger electric trucks, such as the FHB series of electric counterbalance trucks, with their 2 - 3.5-ton capacity, is particularly helpful here. Using attachments reduces the capacity of your forklift truck, but a larger capacity truck will help you maintain load sizes.

To learn more about the key features and specifications of our electric counterbalance forklifts, download the brochure here.

Electric forklifts mean a different way of working. Will this be expensive for my business?

With the change in regulations about powering vehicles coming in the very near future, it's worth thinking about how you will adapt now – considering the best fleet options while you have time, rather than being rushed to make expensive decisions in a hurry.

You will need to consider how you adapt your operations when you go electric. For example, you will need space for equipment like chargers. Electric trucks also need to be stationary when charging, so you will need to allow time for this to happen.

This different way of working means you need to plan for the changes, especially if you work with shift patterns or multi-shift activities. This is another example of when a change in staff mindset will be needed. You will also need to invest time and resources in staff training.

Rather than thinking of this as a potential big spend, however, look at the process as future-proofing for your business, increasing your efficiency and cost-effectiveness, as transitioning to electric will offer savings in the long-term.

At TCM, our order pickers offer precise control and manoeuvrability, enabling operators to navigate narrow aisles and congested warehouse spaces more effectively, enabling operators to improve uptime, which saves money for your business. With improved visibility and positioning capabilities, operators can accurately locate and pick the required items, reducing errors and minimising order fulfilment mistakes. This results in lower costs associated with order corrections, returns, and customer dissatisfaction.

Related read: What Are You Doing to Reduce Your Warehouse’s Environmental Impact: Sustainable Material Handling

Are there different options for how to purchase the truck?

Yes. You can buy, rent or lease depending on what your chosen dealer offers and when you find the right payment structure for you. For example, TCM contracts include maintenance, taking away the headache of finding the right maintenance provider.

Related read: Forklift Contract Hire vs. Purchase – How to Make the Right Choice for Your Business

If you are interested in leases that can be tailored to your needs, visit our TCM Finance page.

Where can I find out more about electric forklifts and how they can reduce material handling costs?

Explore our blog for articles on material handling, maintenance, fleet management and more.

If you have questions, get in touch with your TCM dealer. They will take a consultative approach to help you identify where you could make savings by achieving better ROI and TCO in your forklift fleet.

From determining the types of forklifts you need to understanding which financial option works best for you, our Warehouse Manager’s Handbook will help you assess your overall business needs and objectives.