LPG Forklifts.

With a robust frame combined with a good weight ratio and responsive engine, these LPG fork trucks can carry heavy loads from 1.5 to 5.5 tonnes at an efficient pace. Taking a matter of minutes to refuel, our LPG forklift trucks can maintain high power throughout the day for enhanced productivity. Powerful performance meets agility with a compact design that makes it able to manoeuvre with ease.

FGM15-35

Our lightweight FGM 15-35 forklift is designed with efficiency in mind. While its compact frame enables it to reach all areas so that no space is wasted, its fuel-saver mode ensures your fuel doesn’t go to waste - reducing consumption by up to 18%.

FGM40-55

With a lifting capacity of up to 5.5 tonnes, our Fgm 40-55 LPG counterbalance forklift provides optimal flexibility lifting heavier loads while ensuring operator comfort through customisable options and advanced safety features.

All Round Visibility

From the standard lighting package, which includes two forward LED work lights, to the absence of crossbars in the overhead guard and the specially designed mast, the design of the forklift allows for improved visibility in all directions during operations.

Operator Compartment

- Three-point access - easy entry with reduced operator step height.

- Large floor space and 'through the floor' pedals - provide maximum operator comfort for longer shifts.

- Fully adjustable seating - for optimum position and comfort.

- The Grammer vinyl seat comes as standard and is designed with adjustable forward, backwards and backrest angle movement, added lumbar support in the back cushion and an anti-cinch high visibility seat belt brightly coloured to prompt use - creating a comfortable work environment for operators of varying heights.

- An optional cloth seat is available for additional support during long shifts.

Effortless Control

Optional fingertip control armrest provides with low-effort levers and length/ height adjustment, all while increasing precision and control.

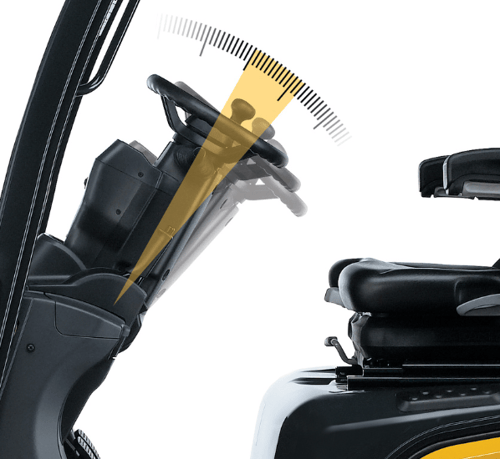

Memory Tilt Steering Column

Infinite adjustment in a 12 degree range, the steering column's "memory" retains operator-preferred setting for swift changeovers.

Frequently Asked Questions.

Unlike other types of forklifts, a counterbalance forklift doesn’t have any outriggers or additional support structures. Instead, it relies on its heavy counterweight located at the rear of the machine to balance the weight of the load being lifted. This unique design allows the forklift to navigate tight spaces and reach high shelves without any obstacles.

As any operator will tell you, handling a counterbalance forklift requires skill and precision. First, ensure that you’re wearing the appropriate safety gear, including a hard hat and hi-vis (high-visibility) vest. Before starting the forklift, conduct a thorough inspection to ensure that all the controls and safety features are in working order. Once inside the forklift, adjust the seat and mirrors for optimum visibility. To start the engine, turn the key and allow it to warm up. Familiarise yourself with the controls, such as the accelerator and brake. When moving the forklift, always keep a clear line of sight and maintain a safe speed. Take extra caution when turning or reversing, as the counterbalance forklift is rear-wheel drive. To lift and transport loads, approach slowly and position the forks carefully before raising them to the desired height. Always make sure the load is balanced and secure before moving.

.png?width=50)

.png?width=50)